The Role of Simulation in the Construction Industry

The construction industry is under immense pressure to undergo a digital transformation, including decarbonizing their delivered assets’ life cycle, coupled with the constantly present focus on cost savings.

Latest News

May 26, 2021

Simulation in Construction

The construction industry has been slow to adopt digital or online methods of working and collaborating, although an upward trend is slowly pushing the transformation where it needs to go. In part, this has been driven by the emergence of easily-accessible cloud-native apps with SaaS business models to attract construction firms of all sizes.

Simulation technology has adopted high-performance cloud computing, and by doing so has made recent strides and advances in speed and accuracy. Designers and builders need access to fast and accurate simulation tools that quantify their buildings’ physical, environmental and energy performance in one platform.

This article explores why at each stage of the building lifecycle (Table 1), appropriate simulation tools must be applied throughout the design process, and show how leading architecture and engineering firms worldwide are leveraging the power of simulation to create our future built environment.

Table 1 shows the main stages of a building lifecycle (Adapted from the RIBA Plan of Work 2020) and where powerful simulation tools such as computational fluid dynamics (CFD) can offer insight, demonstrate compliance with building regulations and improve building performance. An effective simulation tool will enable multi-disciplinary design teams to collaborate effectively and provide solutions for architects, MEP, structural engineers and the energy and sustainability consultants on the team.

Ideally, all design team members can work from the same BIM model, using simulation at key touchpoints to verify designs, quantify performance and iterate fast, based on sound engineering and readily available physics-based solvers.

The Building Life Cycle

How Do Architects Use Simulation?

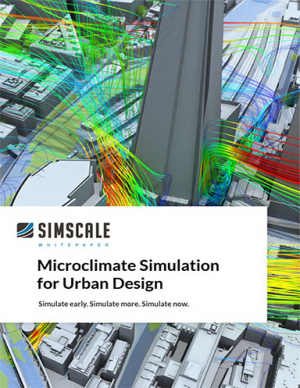

Zaha Hadid, a globally recognized architecture and design firm, uses microclimate simulation in designing buildings early. Zaha Hadid works on some of the most creatively challenging projects that push the boundaries of architecture. Their projects tend to be non-standard shapes and structures that are instantly recognizable.

Bringing in an environmental perspective from the beginning is crucial as every subsequent step is facilitated by solving design challenges early. The OPPO headquarters in Shenzhen, China (Figure 1) is a good example. The building is 200 meters tall and 185,000 square meters with a retail and prestigious office space mix. The structure and surrounding site required analysis to evaluate its microclimate and sustainability performance. External wind simulation was used to optimize the building’s aerodynamic shape, assess pedestrian wind comfort, and consider the wind loading and structural implications. According to Hadid, “The earlier you use simulation in the design process, the more chances you have to produce a sustainable building.”

Adrian Smith and Gordon Gill (AS+GG) is another leading design firm specializing in high-performance, sustainable architecture on an international scale. AS+GG’s practice includes designers with extensive experience in multiple disciplines, including architecture, interior design, urban planning and sustainability.

They have been long-time users of advanced simulation tools for embedding environmental and sustainability principles in their projects. Their approach to integrated design emphasizes a relationship with the natural and surrounding environment.

Among the firm’s many projects are designed for high-rise buildings, where the building form can drastically influence overall project sustainability. AS+GG needs to test designs as early in the design process as possible, especially during the “competition” phase when early validation allows for multiple iterations and exploration of new design directions.

Simulating various designs of a tower (Figure 2), for example, showed that wind forces could be reduced by 35% by tapering and stepping the shape of the building. The same simulation was used to evaluate wind comfort and safety. For AS+GG, simulating early and often is now best practice adopted on all significant projects and ensures that climate-driven considerations influence the design early on, rather than being adapted to later on.

How Do Engineers Use Simulation?

Mott MacDonald, a leading global engineering firm with 135 offices in more than 50 countries, uses simulation as a core component of its project design workflow. The application of CFD and other simulation tools is a critical part of embedding sustainability into their projects. For example, working on large projects, including a sports stadium (Figure 3), Mott MacDonald used cloud-based simulation software to simulate wind in and around the building. This type of analysis is essential when trying to capture the wind effects at a particular geographical location. It is then used to run a transient wind simulation to evaluate the impacts of a natural wind on-site comfort and safety.

The same simulation is used to assess the potential for natural ventilation and thermal comfort. Using customized wind profiles, it is possible to look at future climates to see the impact of more frequent storm events.

Mott MacDonald assessed the probability of exceeding certain wind speeds inside the stadium using CFD, which can help look at wind patterns across the turf that may affect gameplay. The results show the impact of wind on an actual football (soccer) game and how it might adversely impact the ball’s movement in the air. An ability to run multiple parallel scenarios will allow an engineer to evaluate several design variants simultaneously, essential for converging on a final design.

Thornton Tomasetti is another leading engineering and design consultancy with more than 1,500 architects, engineers and professionals in 50 offices worldwide. They work on some of the most innovative and award-winning buildings, structures and infrastructure projects across the world. At the heart of their unique set of skills is a CORE Studio team, who research and develop novel design technologies in-house to support their designers’ creative power.

Thornton Tomasetti was an early adopter of next-generation simulation technology designed to run on the cloud. They even went one step further and integrated these simulation tools into their preferred CAD software by creating a novel app (Figure 4).

The app allows architects and engineers to quickly evaluate a building or masterplan’s microclimate using transient CFD analyses that are an order of magnitude faster than traditional on-premises CFD software. This gave Thornton Tomasetti the capability to iterate their designs quicker and at earlier stages of the design process.

Connected Construction

BIM and other CAD tools used by architects and engineers must seamlessly integrate with analysis packages. Cloud tools that offer flexible access and integration with existing workflows are the easiest way to embed good practice, that is, simulating designs regularly throughout the building lifecycle.

More SimScale Coverage

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

Related Topics