December 10, 2019

The word “visionary” is often used to describe those who imagined a future that the rest of us didn’t.

At Aras, we often think of them as resilient thinkers—their flexible approach to tackling problems is a key to their success. Of course, being able to think “out-of-the-box,” imagining new ways to build the future, is one thing—but will these resilient thinkers have the tools and processes that they need to make their vision a reality?

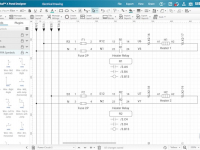

In the world of product development software, a resilient PLM platform has two critical objectives: it accommodates whatever is needed today and it can evolve to meet tomorrow’s unknown challenges.

What is a resilient platform? At Aras, we define a resilient platform as one that adapts to changing business requirements while never locking users into a specific technology. It is a platform that is made to be upgraded while maintaining all previous customizations and one in which the data is fully transparent.

Is your PLM platform “resilient?” Here are the three key design principles brought to you by the resilient thinkers at Aras.

Fill out the information below to download the resource.

Latest News

Related Topics