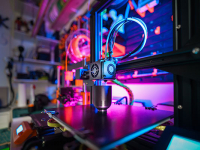

Design for Additive Manufacturing

Decades in the making, additive manufacturing is moving to the forefront of innovation as emerging capabilities, advanced materials and lower-cost alternatives position the technology as a compelling addition to mainstream production practices.

For additive manufacturing to be a catalyst for true innovation, engineers will need to venture outside the rules of traditional assessment frameworks and understand AM’s strengths, design constraints and trade-offs.

AM is poised to be a crucial tool for transforming design practices. Yet without the right AM mindset and tools, engineering organizations will reap only partial benefits and miss out on the opportunity for competitive differentiation.

Download this paper to learn more about additive manufacturing.

Fill out the information below to download the resource.

Latest News